How To Buy An Apron

Important Factors in the Selection of an X-ray Apron

The quality demands for X-ray protective clothing are now greater than ever. Wearing times of the protective aprons and other personal protective equipment (PPE) are extended by modern, radiologically supported procedure in diagnostics and treatment. The protection requirements differ depending on the intended use. Below you will find recommendations and advice for selecting your protective clothing in order to ensure a perfect balance of radiation protection, weight and comfort.

The Special Cut of a Radiation Protective Apron

When deciding between different radiation protective aprons, particularly if you will be wearing them for long periods of time, weight is probably one of the most important criteria. This criteria is primarily, among other factors, defined by the cut.

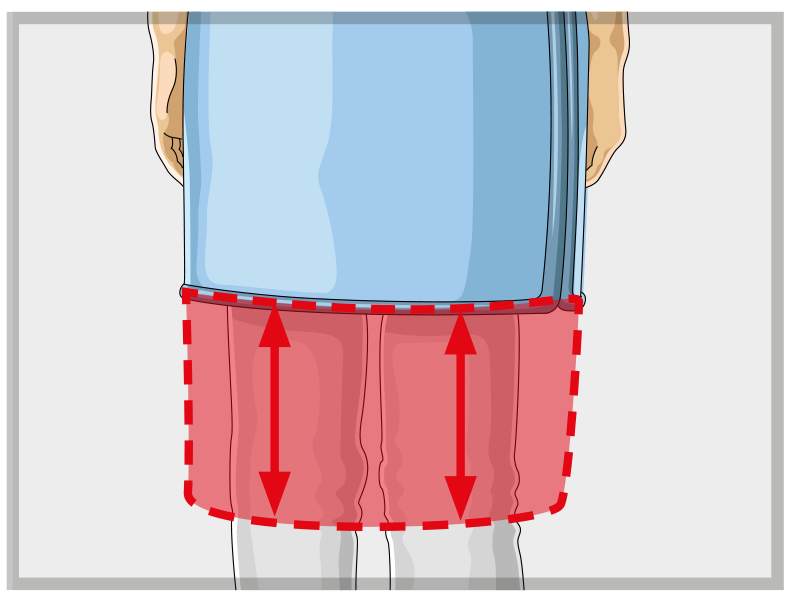

A very short costume skirt or a short apron/coat will of course reduce the weight of the protective clothing. However, an apron of sufficient length should always be used to ensure comprehensive protection. There is hematopoietic bone marrow located in the knee joint, which is why IEC 61331-3:2014 / DIN EN 61331-3:2016 state that: § «Protective aprons shall be designed to cover … down to at least the knees».

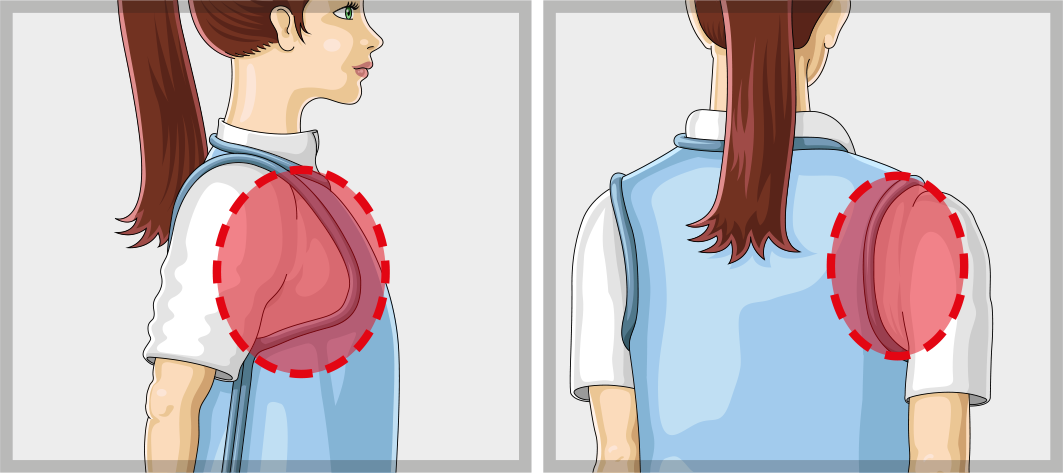

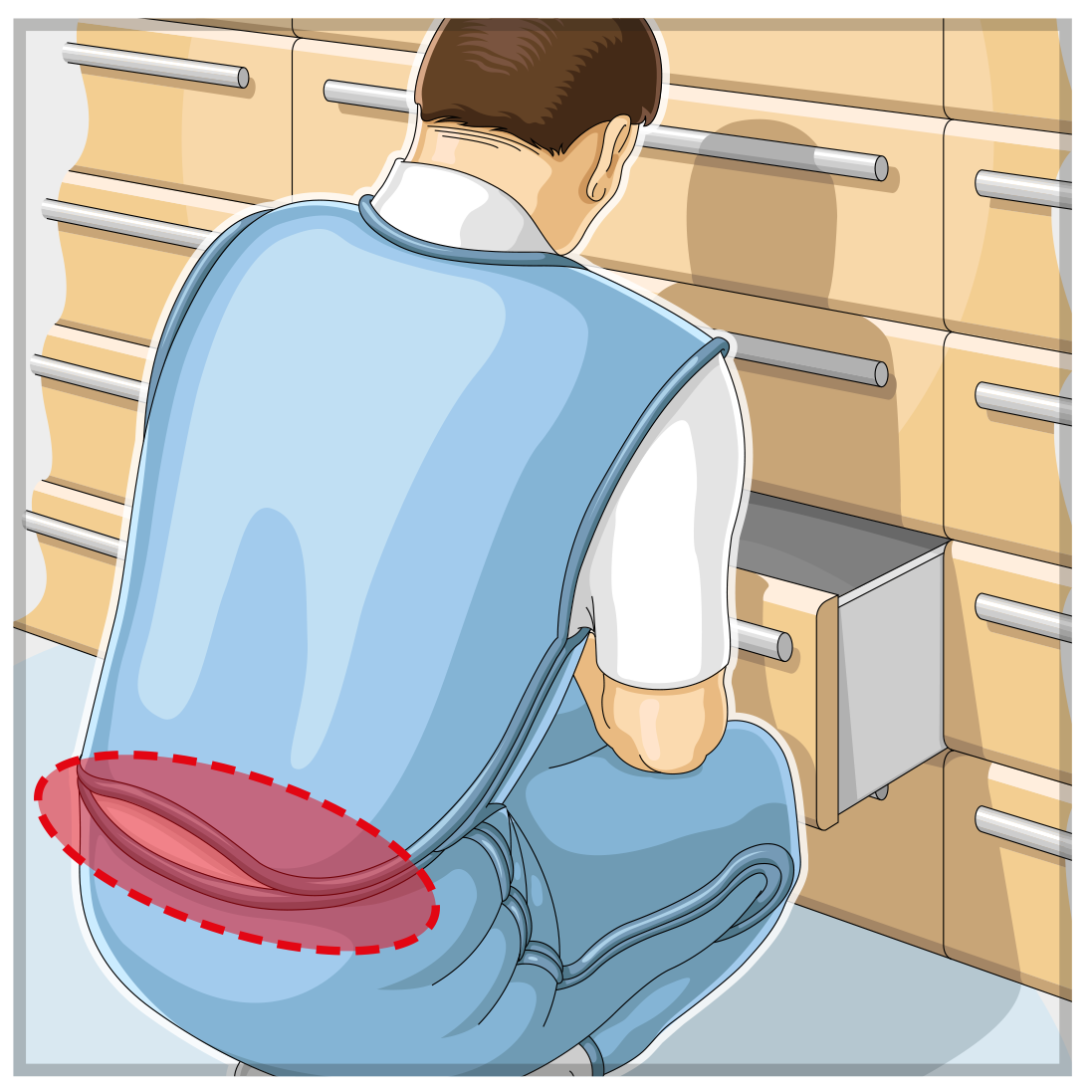

An apron that is too large will have two negative consequences: The apron is heavier than required and there may be gaps in the protected areas, e.g. caused by armholes which are too large. Particularly with women, this can lead to breast tissue being exposed which is classified as particularly sensitive. Having an armhole that is too large can result in breast tissue being exposed. An armhole which extends too far across the back does not ensure a sufficient level of protection. Armholes should follow the ALARA principle: As small as possible and only as large as absolutely necessary («ALARA» – As Low As Reasonably Achievable).

The weight of a radiation protective apron is easy to assess if you have an opportunity to try it on. Of course, the most important thing is that you select the correct size. While a radiation protective apron which is too small is indeed lighter, it does not guarantee adequate protection. Therefore, when choosing a suitable radiation protective apron you should also pay special attention to weight relief systems. These systems distribute the weight of the radiation protection apron ergonomically and in doing so, significantly increases the wearing comfort for the user.

In general, there are two different systems available:

- The radiation protective apron is split up into two pieces (costume) with a vest and a skirt. This way, the hips carry a significant part of the weight of the apron and relieve the shoulders. Additionally, the weight of the skirt can be borne comfortably by the hips with a wide stretch insert integrated in the back of the skirt

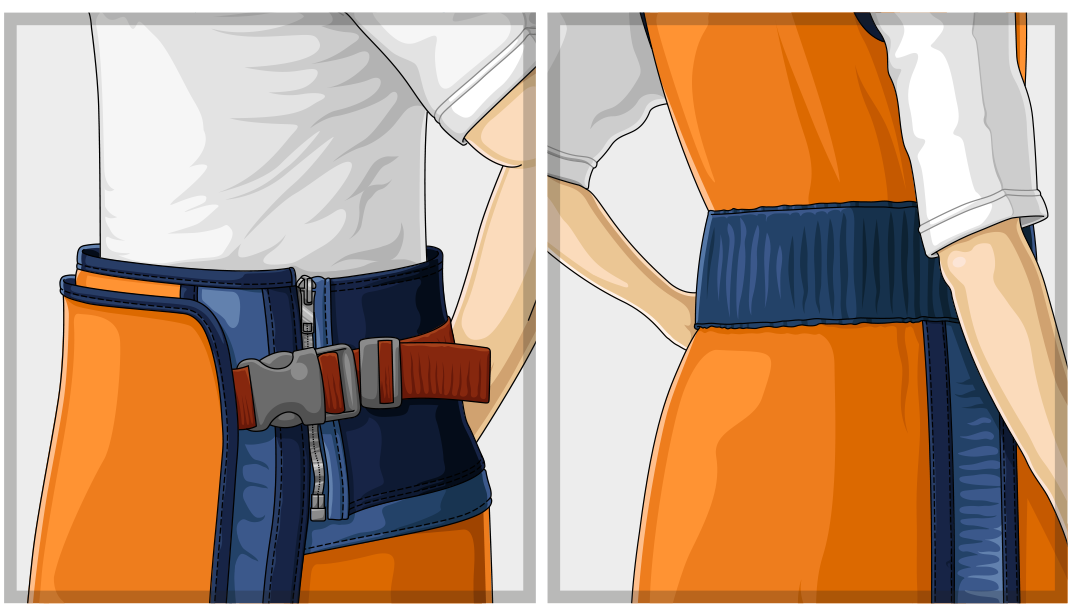

- If you are wearing an apron / one-piece coat the weight can again be distributed to the hips with a stretch belt that runs around the body

Tip: When closing the belt of the coat, lift your shoulders up slightly. Thus, the weight of the coat will partially rest on the hips and will not be completely borne by the shoulders.

Skirt with stretch insert and Coat with stretch belt. Also when wearing front protective aprons the shoulders can be relieved from the total weight burden. Clever inclusions of stretch inserts redistribute the weight and support the back. In order to avoid placing any additional load on the shoulders, radiation protective aprons should always be fitted with soft shoulder pads.

There are two different designs:

I. Both front panels of the protective apron have the specified lead equivalent value

The only advantage of this option is that the user is always protected with at least the specified lead equivalent value after closing the apron. Disadvantage: Due to the design, there is always an area of overlap, which has twice the lead equivalent value. Consequently, you have to carry more weight than necessary.

II. Both front panels have roughly half the lead equivalent value – overlapping ensures the specified lead equivalent value

In terms of weight, option II is better than option I. However, you need to be aware that the desired lead equivalent value is only achieved in the overlapping area. You should specifically check with the apron manufacturer whether the shoulder parts, where the front panels a lot of times do not overlap, have the full lead equivalent value. In addition, it may happen that the apron is not closed correctly, e.g. due to carelessness. As a result, there may be areas with only half of the specified lead equivalent value.

MAVIG has solved these problems with their patented «Safety Zones». The areas on the sides and on the shoulders separated by seams in the outer material already have the full lead equivalent value. Thus, the shoulder parts are optimally protected and the safety zone on the side makes it easy to correctly adjust the front panels.In order to visually differentiate the safety zones, they are always manufactured in the colour «Titan», regardless of the colour of the apron.

TIP: The safety zones are also an ideal help to check if the correct apron size is chosen. If the front panel ends in the safety zone, the size is right for you.

If the overlapping area between vest and skirt on the back is not sufficient, it will result in gaps in the radiation protection when bending. Therefore, for radiation protective reasons, it does not make sense to chose a particularly short vest in order to reduce the total weight of the apron. An inadequate overlap of the vest and skirt is dangerous, for example when bending over.

Lead Equivalent and Protective Materials

Does Lead-Free really mean lighter?

When it comes to radiation protection, you can decide between three different types of protective materials: leaded, lead-reduced and lead-free. Unfortunately, many users still think that “lead-free” translates into a lighter protective material and thus, a particularly light protective apron. However, research proves that wrong. The following brief overview of the different protective materials explains the relationship between material and weight:

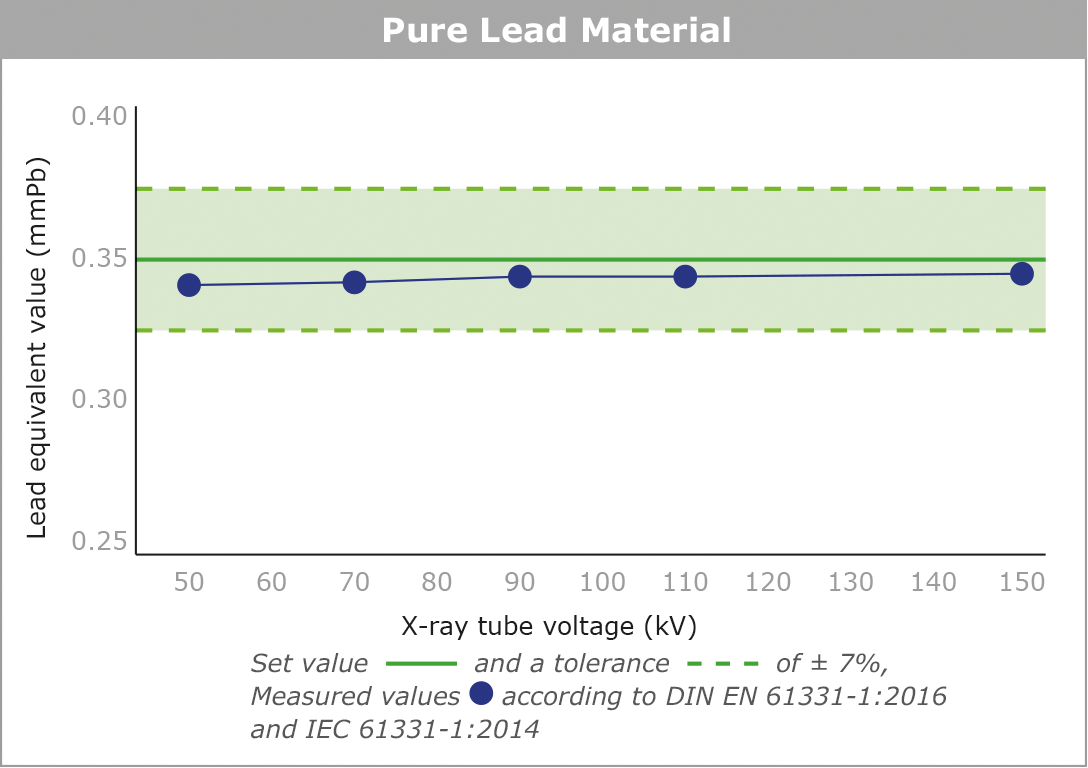

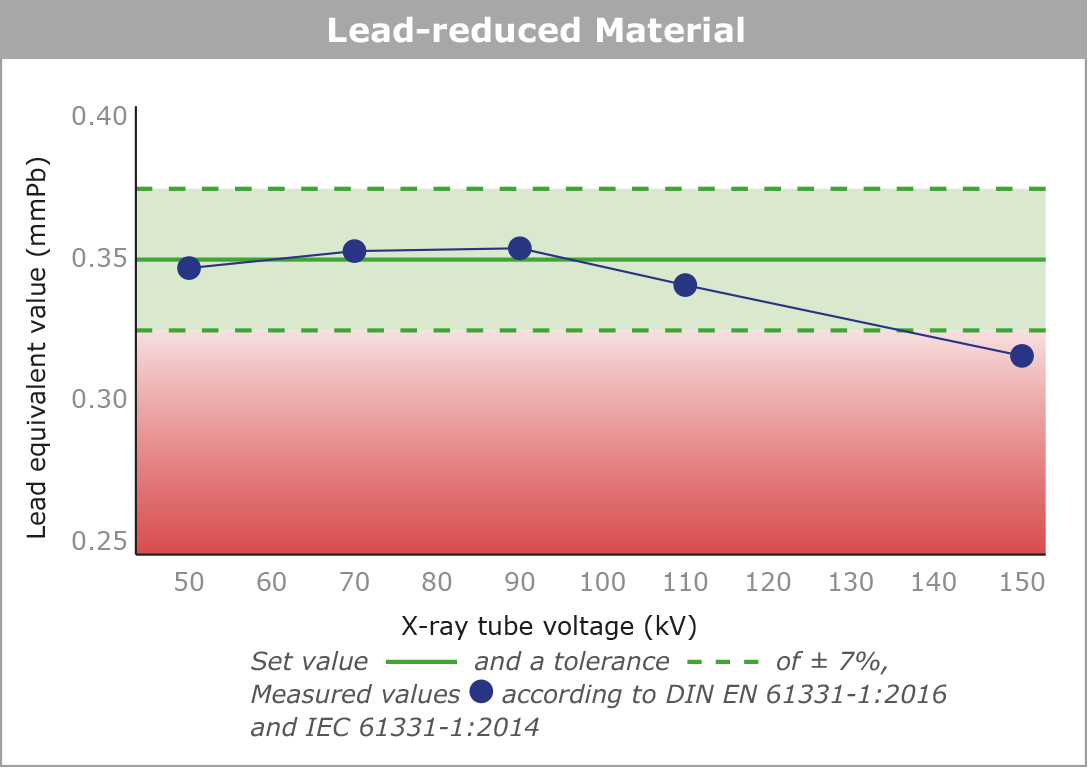

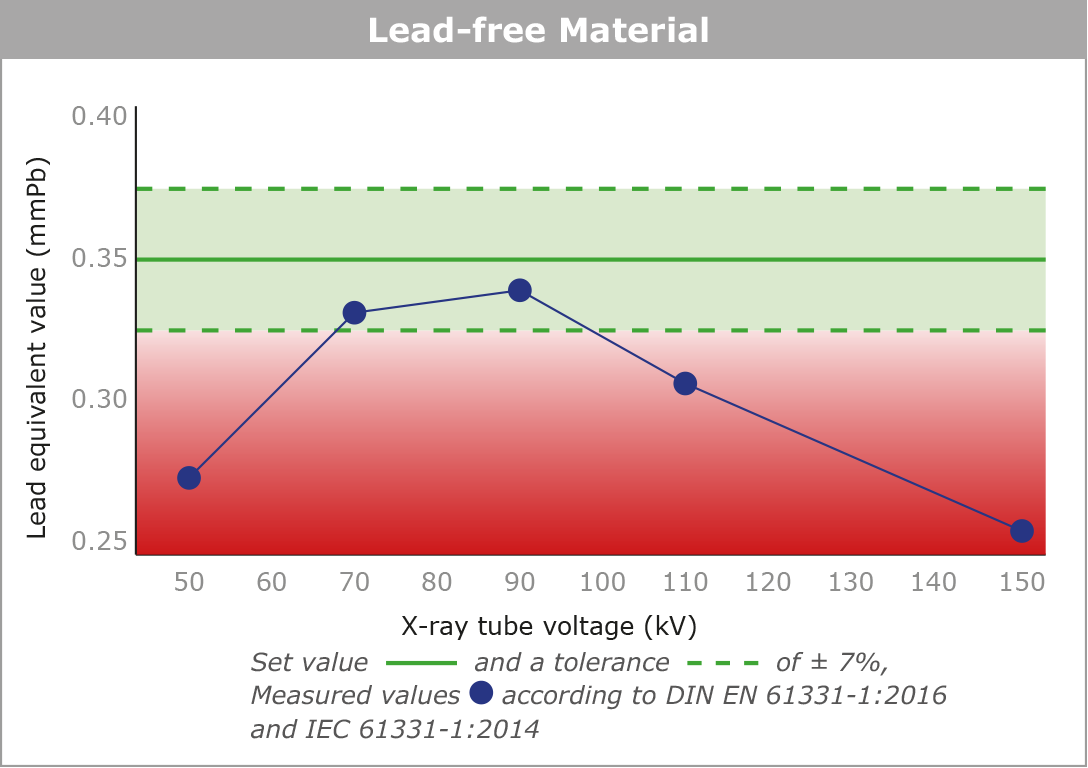

The following graphs illustrate the relationship between the different materials over the entire X-ray tube voltage range of 50 – 150 kV (measured in accordance with the current standard IEC 61331-1:2014).

The standard protective material for shielding against X-rays is lead. Lead is a high-Z-material, meaning an element with a high atomic number, i.e. a high number of protons. A high-Z-material such as lead is very effective at shielding the user from X-rays in the clinically relevant range of 50 – 150 kV almost irrespective of the X-ray tube voltage. So, protective materials with lead have a stable lead equivalent value from 50 – 150 kV. On the downside, a high atomic number means that the protective material has a higher weight.

The standard protective material for shielding against X-rays is lead. Lead is a high-Z-material, meaning an element with a high atomic number, i.e. a high number of protons. A high-Z-material such as lead is very effective at shielding the user from X-rays in the clinically relevant range of 50 – 150 kV almost irrespective of the X-ray tube voltage. So, protective materials with lead have a stable lead equivalent value from 50 – 150 kV. On the downside, a high atomic number means that the protective material has a higher weight.

In lead-free protective materials, lead is completely replaced by another material, which usually has a lower atomic number. Depending on the material, it may be the case that the protective material is considerably lighter for the same surface area. But, as mentioned above, low-Z-materials provide lower protection against certain X-Ray tube voltages than pure lead materials. As lead is completely replaced in lead-free materials, this can cause significant changes in the lead equivalent value, depending on the X-Ray tube voltage. In this case, many times the specified lead equivalent of the protective material is only met at certain x-ray tube voltages. If a different voltage is used, the user’s protection may be significantly lower than expected. But that doesn’t mean that lead-free radiation protective aprons cannot guarantee adequate protection. For example, if you completely replace lead with bismuth, you will be just as protected. On the other hand, as bismuth is directly next to lead in the periodic table, the radiation protective apron would not be lighter.

It is particularly important to ensure that the material does not emit any fluorescent radiation. This is prevented by the two-layer structure of the MAVIG Leadfree Material.

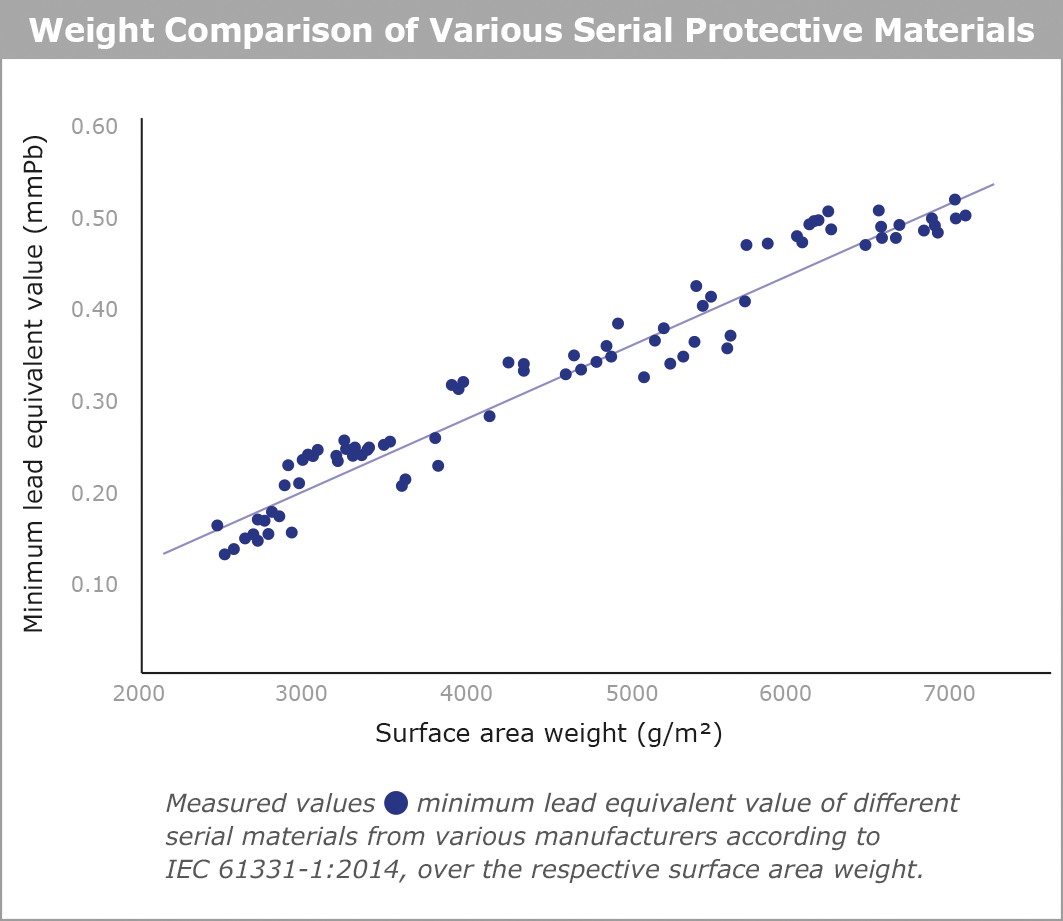

Generally speaking, any material can provide sufficient protection if it is configured correctly. Currently, this is only ensured through the norms IEC 61331:2014 / DIN EN 61331:2016. In order to be adequately protected over the entire X-Ray tube voltage range, it is important that the radiation protective apron maintains a certain weight. This picture shows the lead equivalent values of different serial materials from various manufacturers, determined from 50 kV – 150 kV according to IEC 61331-1:2014. From the determined lead equivalent values, the lowest value was plotted over the surface area weight of the respective material. It is clear that a lower surface area weight goes hand in hand with a lower lead equivalent value and therefore a lower level of protection. The same applies vice versa. A higher lead equivalent value with a correspondingly higher level of protection usually has a higher surface area weight.

The Right Radiation Protective Apron

The lead equivalent value required for your workplace depends on the working conditions (radiation protection present on-site, X-Ray tube voltage, position in the room, etc.) and cannot be determined generally. In Germany, radiation protection commissioners monitor and supervise the measures taken to ensure adequate radiation protection in environments where ionizing radiation is used. If you have questions about radiation protection, this person is the first point of contact at your workplace. Apart from that, each person that wears a radiation protective apron should be assured that he or she is properly protected with the lead equivalent value mentioned on the radiation protective clothing in the X-ray tube voltage range that they need. To that end, always make sure that the lead equivalent value of your radiation protective clothing complies with the current standard IEC 61331-1:2014 or DIN EN 61331-1:2016. Further, you should check in which X-ray tube voltage range you work and for which range your preferred protective clothing is approved for. For example, if you only work at 80 kV – 100 kV, the lighter protective clothing made from reduced-lead / lead-free material, which is mostly tested in and approved for the 50 kV – 110 kV range, is best. On the other hand, for procedures, such as CT interventions, it is imperative that the material has been tested and approved for the entire X-ray tube voltage range from 50 kV – 150 kV. In this case, MAVIG recommends that you use pure lead or an equivalent protective material.

Why are Some Aprons Significantly Lighter than Others?

Today, it is still possible that some aprons are significantly lighter than others. This is due to the fact that not all manufacturers have changed their production to the latest technology (IEC 61331-1:2014 / DIN EN 61331-1:2016). Radiation protective clothing, which was approved before the introduction of the new standards, retains its CE certification for the time being, which is why it is particularly important to pay attention to the year of the norms/standards.

Why does the lead equivalent value fluctuate with a partial or complete replacement of lead? And why can some radiation protective aprons receive a CE certification despite having a suspiciously light weight?

To clarify these questions, we must take a closer look at the measurement methods used in the past and today to determine the lead equivalent value.

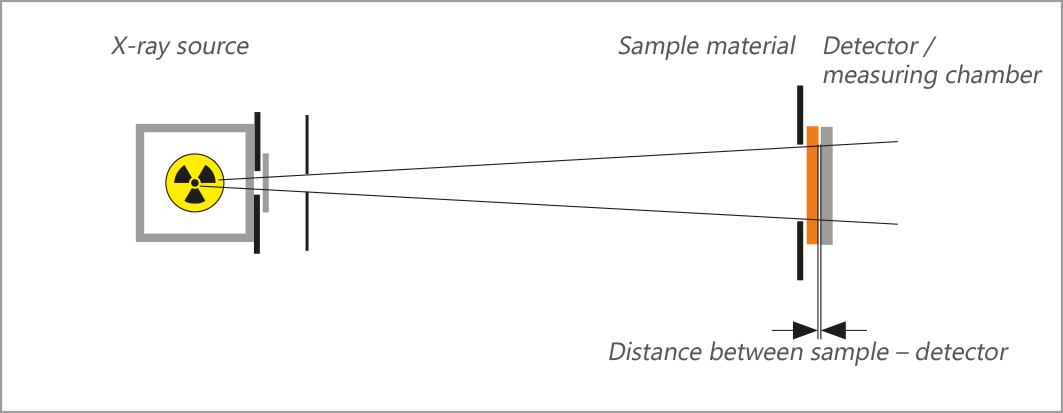

In these standards, the lead equivalent value of a protective material is determined in the narrow beam condition. However, going into the technical details of the determination of the lead equivalent value would go outside the boundaries of this leaflet. What is important to know: When taking the measurement, the measuring chamber is not placed directly behind the sample (the protective material).

Fluorescence Radiation and X-ray Tube Voltages

As a matter of fact, measurement method II, although in a slightly modified form, has been required by the German standard DIN 6857-1:2009 since 2009. Due to the update of the standard series 61331, this norm has been withdrawn. If we have a material that contains just lead, both measurement methods will give a similar lead equivalent value. However, if the measurement method from category I is used with lead-reduced and lead-free materials, a false result would be given, and the lead equivalent value would be shown to be higher than it actually is. The reason for this are the «non-lead materials».

Certain «non-lead materials» emit a secondary radiation, so-called fluorescence radiation, when subject to typical medical X-ray tube voltages (80 kV – 100 kV). This fluorescence radiation is low-energy and only has a very small range in the air. Therefore, fluorescence radiation can only be measured directly behind the radiation protection material. If, like with category I, the measuring chamber and the sample are far apart, the fluorescence radiation will not be detected, and therefore the lead equivalent value will be incorrectly measured as higher than its actual value. Consequently, a correct lead equivalent value for all materials can only be determined by using the category II measurement method (or the withdrawn DIN 6857-1:2009).

Moreover, the fluorescence radiation has a greater effect from a biological point of view than the higher-energy scattered radiation that the apron blocks.

In addition, the Category I standards required the determination of the lead equivalent at only one single X-ray tube voltage. As previously shown, the lead equivalent for lead-free or lead-reduced protective materials is highest around an X-ray tube voltage of about 90 kV. Therefore, if one selects this voltage for the determination of the lead equivalent according to the outdated measuring methodology I, the standard would be officially fulfilled, but the wearer would unknowingly be protected far less than assumed when working with other X-ray tube voltages.

Downloads

How to Buy An Apron – Flyer

(PDF-Download)

X-Ray-Apron Checklist

(PDF-Download)

Made to Measure for MAVIG X-Ray-Aprons (Standard collection)

(PDF-Download)

Made to Measure for MAVIG X-Ray-Aprons (Levio Edition)

(PDF-Download)

All sources and further additional information can be found in our flyer « How To Buy An Apron» .