Home > UT70 Advantages/ Modifications

Changes to the table-mounted lower body protection system UT70

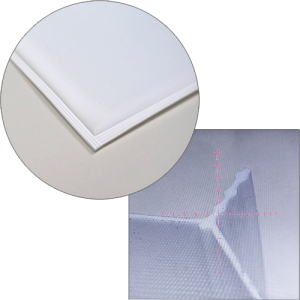

The outer cover of the flexible X-ray protective shields is now made of the recyclable material TPU (thermoplastic polyurethane). This material is extremely resistant to tension and tearing, phthalate-free and can be easily disinfected with commercially available cleaning agents. The material‘s compatibility with the radiation protection material has been proven in climate chamber tests.

The main part of the UT70 can now be fixed to the table rail using a rotary knob.

The welded seams of the flexible X-ray protective shields are now even more stable and durable thanks to wave forming and triple welding. High-frequency welding is a new and patented manufacturing process that guarantees an extremely long service life for the TPU material and the shields.

The retaining clips of the removable upper parts have been reinforced and enlarged, as well as their attachment optimized.

In the future, the connecting joint will be welded instead of bolted as it currently is. This ensures maximum strength and rigidity over the entire length of the system.

*Implementation Q1/2024